Project overview

The Danube Removals Project is a full chain CCS project that will annually sequester 500,000 tonnes of advanced biorefinery biogenic CO2 in order to generate CFCR Regulation-compliant voluntary carbon market removal certificates (“Certificates“). The Project is owned by Danube CCS Ventures Kft., a special purpose Hungarian limited liability company (“DCV“), and sponsored by Ireland’s ClonBio Group Limited and the UK’s EMOV Limited.

The Project is the lowest cost CCS effort in Europe. With a capital cost of €80 million, and an annual operating cost of €14 million, the Project showcases the advantages of both onshore saline aquifers as CCS sinks and the reality that fermentation processes (like ethanol, beer, distilleries, biogas plants and some food production) have the world’s absolute lowest costs of carbon capture.

While the Project is focused on Europe’s largest fermentation plant, the Project parameters are highly replicable. Europe has another 10 million tonnes of fermentation CO2 that is currently being vented to the atmosphere and that could be used for other CCS projects. Moreover, the EU’s ReFuel biomethane ambitions would mean bringing another 30 million tonnes of fermentation CO2 into operation over the next decade. For the nascent carbon removals market in the EU under the CFCR Regulation, fermentation is the most promising source going forward of reasonably priced Certificates at scale that meet each of the QU.A.L.ITY prongs of the CFCR Regulation.

Project CO2

Project CO2 all comes from Pannonia Bio Zrt., Europe’s largest and the world’s most technologically advanced grain biorefinery. Pannonia has 50 scientists and engineers on site developing new products, processes and energy efficiency measures as part of the company’s in-house innovation, which is shown here: youtu.be/CZZqtTugeWI?si=G5c2IeIlvo0PRSSe.

Pannonia Technology Firsts

|

Corn Protein Concentrate |

| Barley Protein Concentrate |

| Soluble Corn Protein Isolate |

| Soluble Barley Protein Isolate |

| Ethanol Mechanical Vapor Recompression |

| Soluble Arabinoxylan |

| Front End Dry Corn Fractionation |

| Fiber Organic Fertilizer |

| Corn Fiber Biomethane |

| Barley Fiber Biomethane |

| Bacterial Protein Concentrate |

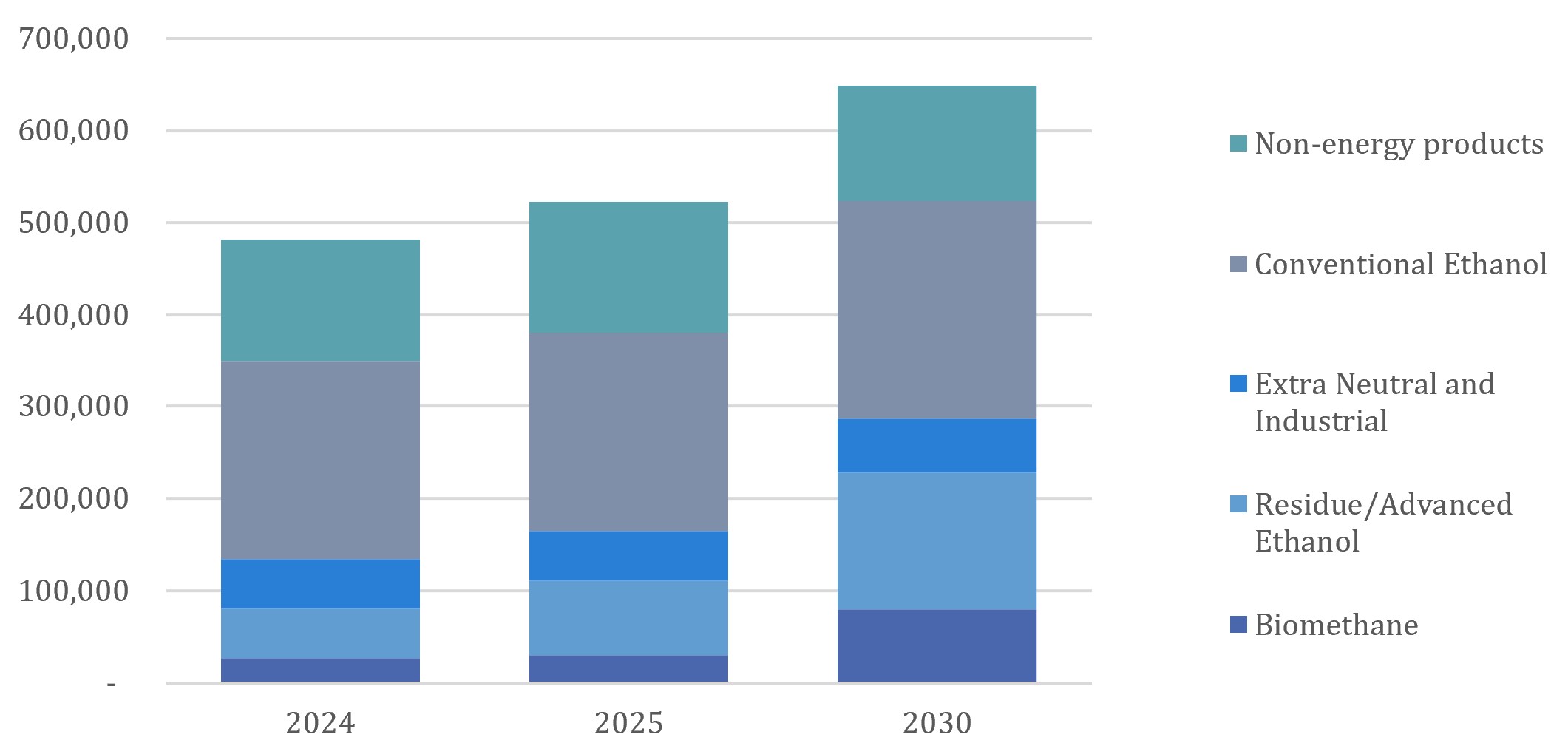

In EU policy Pannonia Bio fits no model as it is not a renewable fuels company, nor a food company, nor an industrial biochemistry company, but rather all of these simultaneously. Pannonia has improved the GHG savings of its ethanol from 57% in 2012 to 75% today. Without CCS, Pannonia anticipates getting to 90% by the end of this decade. With CCS, it should reach 110%. Pannonia’s current biofuels GHG savings result, using the Renewable Energy Directive’s (the “RED“) lifecycle methodology, in over one million tonnes of GHG savings per year.

Over time, Pannonia’s operations have become increasingly centered on the production of protein concentrates and isolates for food markets, on innovative fiber based ingredients for food markets and on the production of waste and residue biofuels, especially advanced biomethane.

Project CO2 Allocation

Currently, most, but not all, barley and corn purchased by Pannonia is certified sustainable under RED. Because Pannonia sells various products that are not covered by the RED or that are produced from process residues and wastes, only a portion of its grain procurement needs to be RED compliant. However, Pannonia has contractually agreed with the Project that any CO2 that it delivers to the Project must ultimately derive from RED certified sustainable grain, so the Project will result in a material expansion of the amount of sustainable biomass that Pannonia uses.

Project Infrastructure

DCV has spent the time and money needed to perform substantial 2D and 3D studies of the target sequestration reservoir, secure a CCS exploration license (granted June 2024) from the Hungarian Mining Authority and fully design and cost the entire Project, include its monitoring, review and verification components.

The Project consists of a compressor station adjacent to Pannonia that will compress CO2 to a supercritical state, and then a 10-15 km pipeline that will take this CO2 to three injection wells nearby. The three injection wells are complemented by two monitoring wells. The critical infrastructure is operated under contract by OGD Green Storage Kft., a special purpose subsidiary of O&GD Central Kft., which is Hungary’s third largest hydrocarbon production company.

All of the Project infrastructure is subject to permitting under the EU’s CCS Directive (as transposed in Hungary). All relevant stakeholders expressly support the Project, including the two affected local communities (Dunaföldvar and Daruszentmiklos) and the relevant regulatory authorities.

Status

At present, the Project needs a further 3D seismic study of limited scope and a test well before it is in a “shovel ready” state. The cost of this remaining work is estimated to be €6.6 million.

DCV’s only material revenue will come from the sale of Certificates. Accordingly, further Project development work depends on securing sufficient offtake commitments or additional equity commitments. Note that the Project has also applied for a grant from the EU Innovation Fund.

The Project invites discussions with all interested stakeholders and investors. Both Pannonia and the Project demonstrate unique levels of innovation, circularity and climate ambition.

Project EU Technology Firsts

| Onshore CCS |

| Total Cost < ETS Price |

| CFCR Regulation Compliant |

| All Biomass Certified Back to Field RED Compliant |

| Fermentation CO2 |

| Beverage/Industrial Alcohol CO2 |

| Conventional Ethanol CO2 |

| Advanced Ethanol CO2 |

| Biomethane CO2 |

| Advanced Biomethane CO2 |

| Food CO2 |